Precision Machining in Japan

Precision Machining in Japan

PMT CORPORATION which is investment company of PRETEC WORLD has done contracted machining of precision parts for production machines in semiconductor and electric component industries since establishment in 1991.

High machining technology that has been cultivated through meeting to various requirement by customers and own alliance network allows precision machining various materials; tool steel, cemented carbide, ceramics, etc.

More than 20 unit of machining facilities such as Vertical/ Horizontal Machining Center and Surface Grinder in our own plant.

Furthermore, inspection by our QC department with several inspecting/ measuring facilities including Ultra Precision CNC Coordinate Measuring Machine (CMM) enables to ship 99.85% of good products annually (calculated from achievement in past 5 years).

Index

Ceramic Processing

Ceramic Processing

Various ceramic materials such as silicon carbide (SiC), silicon nitride (Si3N4) in addition to alumina or zirconia can be processed in precision.

We not only process materials provided by customers, but also undertake material procurement.

In addition, we undertake request of consult regarding of replacing material from metal to ceramics.

Product life improvement and cost reduction will be expected by physical properties of ceramics such as corrosion, heat and chemical resistance.

Correspondence Table

We offer the ideal processing method depending on customer's request; materials, required accuracy, budget, etc.

Typical examples are shown in following table. For the other materials or methods, please feel free to ask.

| Micro Machining | Grinding | Wire-saw Cutting | |

| Alumina | ★ | ★ | ★ |

| Zirconia | ★ | ★ | ★ |

| Silicon Carbide | ○ | ○ | |

| Silicon Nitride | ○ | ○ | |

| Machinable Ceramics | ★ | ★ | ○ |

★ - Specialty ○ - Possible No Mark - Impossible

Example of Ceramics Processing

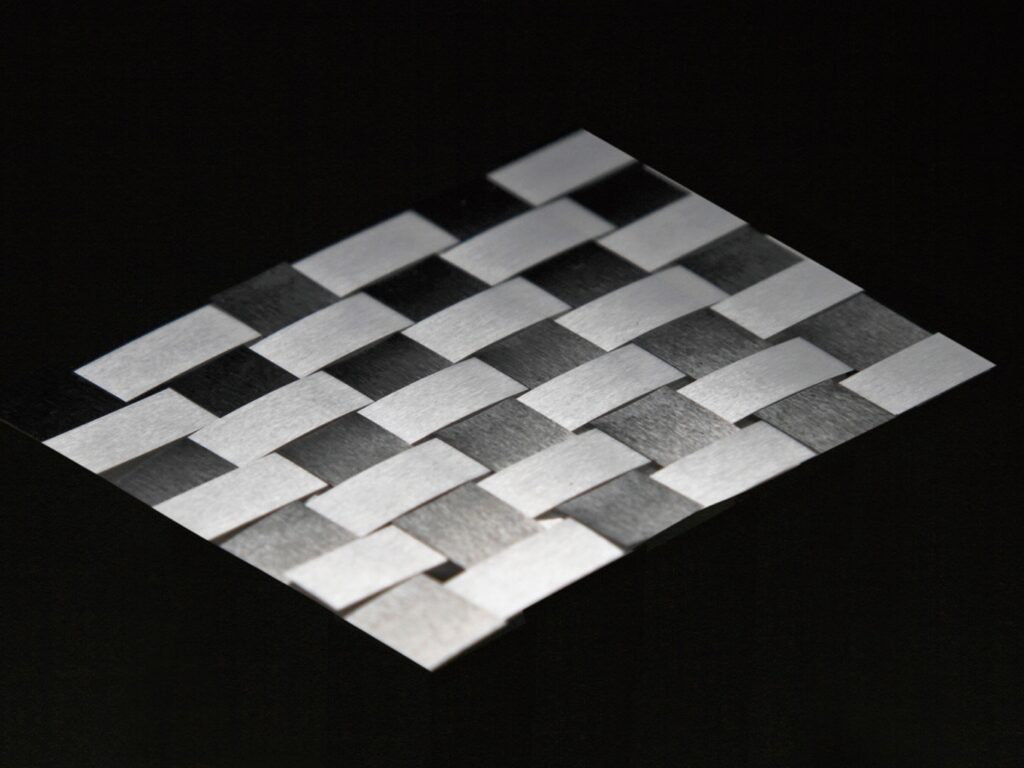

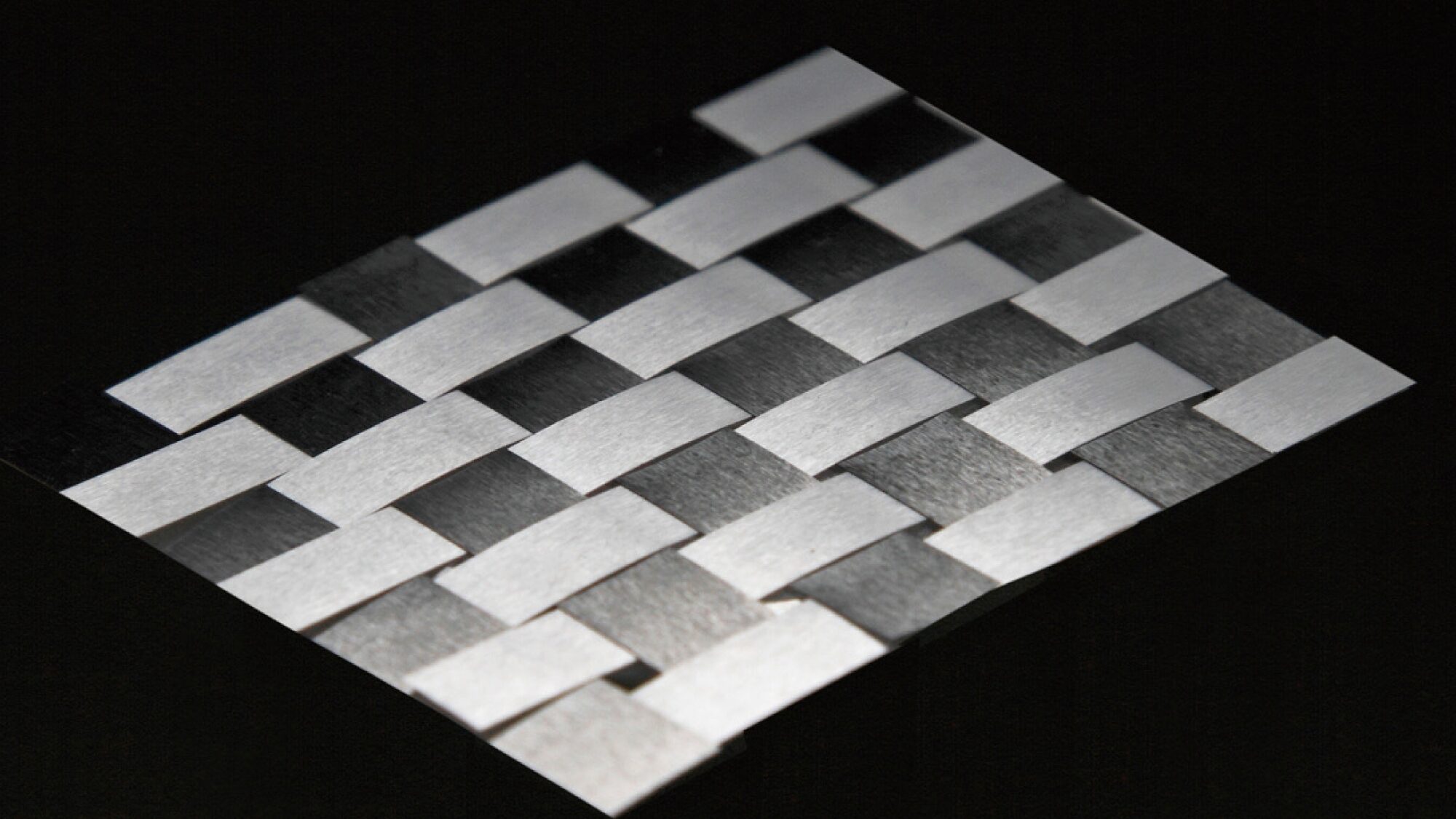

Thin zirconia enough to be knitted

Although this work can be seen as a coaster at first glance, this is knitted white and black zirconia that grinded to thinness of t=15um.

This is not practical items, but is a proof of high grinding technology that making zirconia thin enough to be knitted which has high hardness.

Metal Processing

Metal Processing

In addition to aluminum or stainless, various metal materials can be processed; cemented carbide and tool steel as hard-to-process material with high hardness and 42 alloy or invar as low-expansion alloy.

Integrated production from material procurement to surface treatment is available as per customers request.

Processing small parts up to 200mm sq is our specialty, but middle parts are also possible.

Furthermore, processing brittle materials such as silicon or glass can be undertaken.

Correspondence Table

We offer the ideal processing method depending on customer's request; materials, required accuracy, budget, etc.

Typical examples are shown in following table. For the other materials or methods, please feel free to ask.

| Machining | Grinding | WEDM | Wire-saw Cutting | |

| Stainless | ★ | ★ | ★ | ★ |

| Aluminum | ★ | ★ | ★ | ★ |

| Nickel Alloy | ★ | ○ | ○ | |

| Silicon | ★ | ★ | ||

| Glass | ○ | ★ | ||

| Cemented Carbide | ★ | ★ | ○ | ○ |

★ - Specialty ○ - Possible No Mark - Impossible

Example of Metal Processing

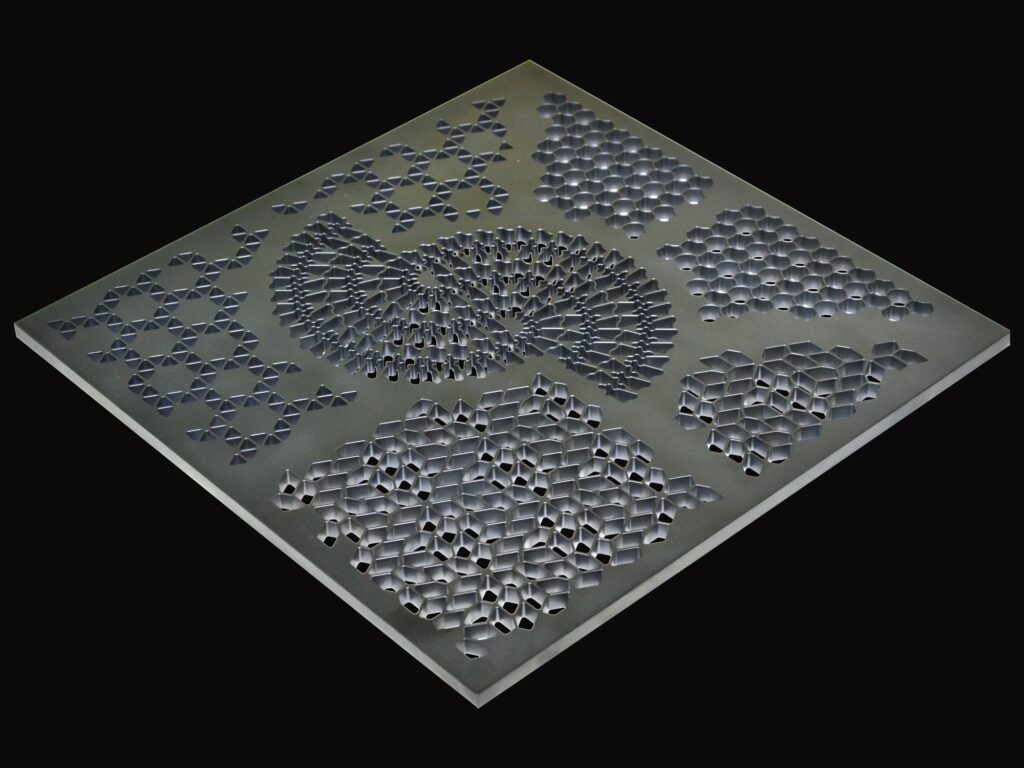

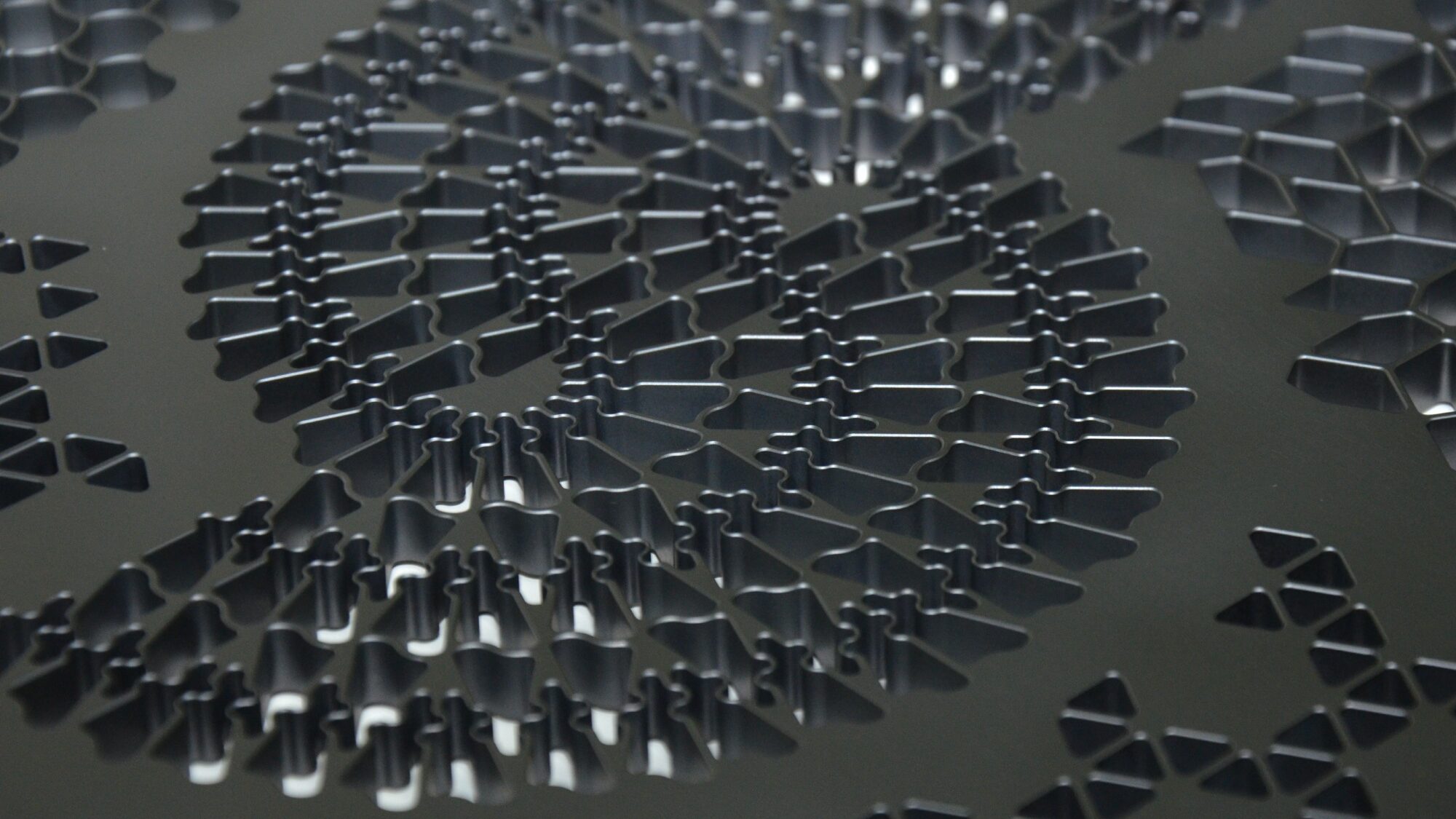

Geometric pattern on hard-to-process material

High machining technology allows processing geometric pattern on 42 alloy which is known as hard-to-process material.

We also can take small lot orders (MOQ: 1pc).

Please feel free to ask.

Own Facilities

Own Facilities

Machining Facilities

Vertical Machining Center

Manufacturer : OKK

Model : VM53R/VM76R

Micro Machining Center

Manufacturer : Roku-Roku Sangyo

Model : MEGA-Ⅲ400

Surface Grinder

Manufacturer : NAGASHIMA SEIKO

Model : NP840-F

| Facility Name | Manufacturer | Number of Own |

|---|---|---|

| Lapping Machine | ― | 1 |

| Surface Grinder | JUNG | 1 |

| Okamoto Machine Tool Works | 3 | |

| Grinding Center | CHI-FA MACHINERY | 3 |

| Horizontal Machining Center | Makino Milling Machine | 1 |

| Vertical Machining Center | Makino Milling Machine | 1 |

| OKK | 9 | |

| DMG MORI | 1 | |

| ROBODRILL | FANUC | 5 |

| WEDM | Pikat | 1 |

| Ultrasonic Cleaning Machine | Crystal Optics | 1 |

| Laser Marker | KEYENCE | 1 |

| Laser Marker (For Ceramics) | Panasonic | 1 |

Measuring or Inspection Facilities

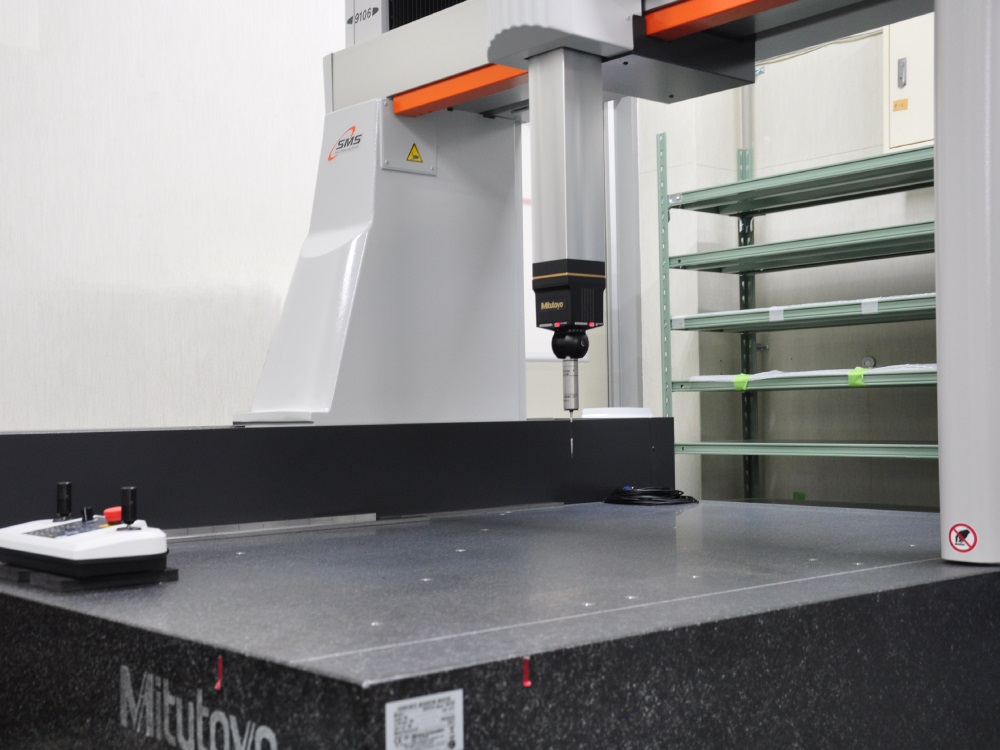

CNC CMM

Manufacturer : Mitsutoyo

Model : CRYSTA-Apex9106

E0,MPE= (2.20+L/1000) um

Ultra High Precision CMM

Manufacturer : Mitsutoyo

Model : LEGEX776

E0,MPE= (0.28+L/1000) um

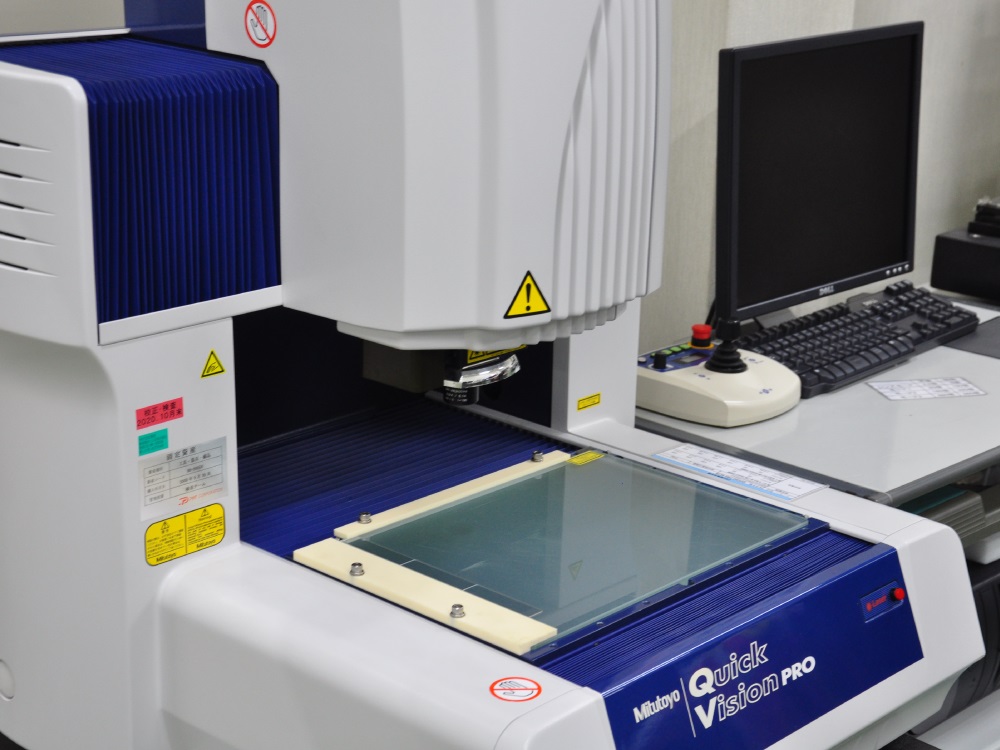

Image Measuring Device

Manufacturer : Mitsutoyo

Model : QVX302-PRO_BL2G

| Facility Name | Manufacturer | Model |

|---|---|---|

| Ultra High Precision CNC CMM | Mitsutoyo | LEGEX776 |

| CNC CMM | Mitsutoyo | CRYSTA-Apex9106 |

| Nano Search Microscope | OLYMPUS | LEXT OLS4500 |

| Image Measuring Device | Mitsutoyo | QVX302-PRO_BL2G |

| Non-contact Surface Measuring Device | Wyko | TOPO-2D/3D |

| Scanning Electron Microscope (SEM) | JEOL | JSM-6460 |

| Laser Measuring System | RENISHAW | ML 10 Gold Standard |

| Toolmaker's Microscope | Nikon | MM-60 |

| Hight Gage | TRIMOS | VERTICAL 3 |

| Surface Roughness Tester | TOKYO SEIMITSU | Surfcom 1400A |

| Autocollimator | Nikon | 6D |

| Measuring Microscope | Mitsutoyo | MF-B3017B |